In the rapidly evolving world of home appliances, staying ahead means choosing brands that combine cutting-edge technology with stylish design and dependable performance. Ciarra Appliances has emerged as a leading name in this space, offering a diverse range of products designed to meet the needs of modern homeowners. With a focus on innovation and quality, Ciarra Appliances aims to transform everyday household tasks into seamless, efficient experiences that enhance overall home living.

One of the standout features of Ciarra Appliances is their commitment to integrating smart technology into their products. From refrigerators with Wi-Fi connectivity to washing machines with programmable cycles, Ciarra ensures that their appliances are not just functional but also intuitive and easy to control. This smart integration allows users to monitor and manage their appliances remotely, bringing convenience to a new level and allowing for smarter household management.

Durability and reliability are at the core of Ciarra’s manufacturing philosophy. Each appliance undergoes strict quality control measures and testing to guarantee longevity and consistent performance. Customers can invest confidently, knowing that their appliances will withstand the test of time and heavy usage. This focus on quality makes Ciarra a trusted brand for families and individuals seeking appliances that combine durability with modern features.

Eco-friendliness is another vital aspect of Ciarra’s product development. best countertop oven Recognizing the importance of sustainability, the brand emphasizes energy-efficient appliances that help reduce electricity bills and minimize environmental impact. Many of their models feature eco modes and high energy ratings, aligning with the global push toward greener living. Choosing Ciarra means making an environmentally conscious decision without sacrificing performance or style.

Aesthetics play a significant role in Ciarra Appliances’ offerings. Their sleek, contemporary designs seamlessly blend into any modern home decor. Whether it’s a minimalist refrigerator, a stylish dishwasher, or a sophisticated oven, Ciarra’s products add an element of elegance and sophistication to your space. This focus on visual appeal ensures that appliances are not only functional but also contribute positively to the overall interior design.

Customer support and after-sales service are integral to Ciarra’s reputation. wall mount range hood The company provides comprehensive warranties, prompt assistance, and a dedicated support network to ensure customer satisfaction. Their commitment to service means that users can enjoy peace of mind, knowing that help is readily available should any issues arise. This customer-first approach has helped Ciarra build a loyal and growing customer base.

In conclusion, Ciarra Appliances stands out as a brand that seamlessly combines innovation, durability, eco-friendliness, and elegant design. As more homeowners seek appliances that enhance their quality of life while respecting the environment, Ciarra continues to lead the way. For those looking to upgrade their homes with reliable, smart, and stylish appliances, Ciarra offers a compelling choice. Embrace the future of home living today with Ciarra Appliances and experience the perfect harmony of technology and design.

The ideal Fit Why an Underwire Bikini Top is a Swimwear Essential

When it arrives to choosing swim wear, comfort and assistance are often at the top of the list. The underwire bikini top has turn out to be a popular option for women searching for both style and stability during their beach or poolside adventures. Unlike traditional bikini tops, underwire options provide additional lift and condition, making them an vital piece for many who desire to feel confident and supported when enjoying water routines or lounging in the sunshine.

One of the primary benefits regarding an underwire swimsuit top is the capacity to offer outstanding bust support. Typically the underwire acts just like a bra, training and shaping typically the bust to produce a lovely silhouette. This characteristic is especially necessary for women with bigger busts who frequently struggle to discover swimwear that gives enough support with out sacrificing style. With the underwire bikini top, you can take pleasure in your time and efforts in typically the water without worrying concerning discomfort or attire malfunctions.

Comfort is definitely a key consideration when selecting swimsuit, and well-designed underwire bikini tops may deliver just that will. Modern designs incorporate padded or seamless underwires that contours to the body, lowering chafing and stress points. Adjustable connectors and multiple catch options also let for a customized fit, ensuring that each woman may find her excellent level of help and comfort. When properly fitted, a great underwire bikini best can feel almost like a second epidermis, providing confidence to be able to move freely.

Supportive swimwear is never compromised with an underwire bikini top. Today’s designs come inside a wide variety of colors, habits, and cuts to be able to suit every individual selection. From classic black and nautical stripes to be able to bold florals in addition to tropical prints, there’s an underwire sting bikini top for every single vibe. Additionally, many brands offer cool details such as ruffles, cut-outs, or perhaps decorative hardware to be able to elevate the look. This versatility assures that you don’t have to sacrifice fashion for functionality.

For many who prefer some sort of more natural appearance, underwire bikini covers can help improve your natural shape, providing a smooth and curved appearance. They are also well suited for generating a balanced figure, especially when used with high-waisted bottoms or matching units. Whether you’re lying down poolside or getting a dip within the ocean, an underwire bikini top makes it possible to feel poised and polished, no issue the occasion.

Proper fit is essential to be able to maximizing the key benefits of a great underwire bikini top. It’s recommended in order to get professionally installed or carefully calculate yourself to locate the right dimensions. An ill-fitting underwire can cause distress, pinching, or searching in to the skin, beating its supportive objective. When fitted appropriately, an underwire swimwear top offers all-day support and assures that you look in addition to feel your better from morning to sunset.

In conclusion, an underwire bikini leading is an adaptable and must-have piece for just about any swimwear selection. It combines assistance, comfort, and fashion in an approach that empowers girls to enjoy their own time in the particular water with full confidence. No matter if you’re heading to a beach vacation, a new pool party, or simply relaxing inside the sunlight, choosing typically the right underwire swimsuit top can make a lot of difference in precisely how you feel and appear. Dive into the next swimwear store shopping with this supportive staple — due to the fact every woman should get to feel gorgeous and supported.

Fuel Pump Fundamentals: The Lifeline of Your Vehicle’s Engine

Introduction: The Heartbeat of the Fuel System

A vehicle’s fuel pump is a crucial component that often goes unnoticed until it malfunctions. Serving as the engine’s lifeline, the fuel pump supplies a steady stream of fuel from the tank to the engine’s combustion chambers. Without it, the vehicle cannot run efficiently or may not start at all. Understanding how a fuel pump works and its importance in vehicle operation can help drivers better maintain their cars and recognize early signs of trouble.

How a Fuel Pump Works: Delivering Power to the Engine

The primary function of a fuel pump is to draw fuel from the tank and push it through fuel lines to the engine at the required pressure. This process ensures that fuel injectors or carburetors receive the precise amount of fuel needed for combustion. Modern fuel pumps are usually electric and integrated into the fuel tank, providing a reliable and consistent supply. Proper fuel pressure maintained by the pump is essential for optimal engine performance and fuel efficiency.

Types of Fuel Pumps and Their Specific Uses

There are mainly two types of fuel pumps: mechanical and electric. turbocharger are typically found in older vehicles with carbureted engines, operating via mechanical linkages connected to the engine. Electric fuel pumps, which dominate today’s automotive landscape, are installed inside the fuel tank and powered by electricity. In-tank pumps are the most common, designed for quiet operation and protection from debris, while in-line pumps are mounted outside the tank for specialized applications.

Common Symptoms of a Failing Fuel Pump

Knowing the signs of a failing fuel pump can save you from unexpected breakdowns. Symptoms include difficulty starting the vehicle, engine sputtering or stalling, loss of power during acceleration, and a whining noise coming from the fuel tank area. You might also notice reduced fuel efficiency or your vehicle refusing to start altogether. Addressing these signs early can help prevent further damage to the engine and related components.

Maintaining and Replacing Your Fuel Pump

While fuel pumps are built to last, they can wear out over time due to debris, corrosion, or electrical issues. Regularly replacing the fuel filter can extend the life of your pump by preventing contaminants from clogging it. If the pump fails, replacement is necessary. Ensuring you choose the right pump for your vehicle and having it installed by professionals can prevent potential leaks or electrical problems that can arise from improper installation.

The Future of Fuel Pump Technology

Innovations in automotive technology are leading to more efficient and durable fuel pump systems. Variable-pressure pumps and smart control modules are being developed to optimize fuel delivery based on real-time engine demands. As electric and hybrid vehicles become more common, fuel pump designs are evolving to accommodate alternative fuels and integrated energy management systems. These advancements aim to improve fuel efficiency, reduce noise, and extend service life.

Conclusion: Keep Your Fuel System in Top Shape

In summary, the fuel pump is an essential component that ensures your vehicle runs smoothly and efficiently. Regular maintenance, prompt attention to warning signs, and understanding its function can help you avoid costly repairs and breakdowns. As technology continues to advance, staying informed about your vehicle’s fuel system will ensure you enjoy reliable performance and prolonged engine life for years to come.

Bringing the Spirit of Quotes Home The Elegance of Australian Art Prints

Australian art styles are a captivating way to celebrate typically the country’s diverse scenery, rich cultural history, and vibrant creative scene. These designs serve as stunning, affordable art pieces that can immediately transform any space, from living areas to offices, directly into a reflection regarding Australia’s unique attraction. Whether you’re some sort of proud Aussie or an admirer regarding Down Under’s herbal wonders and creative traditions, Australian art prints offer a meaningful way to bring a piece of Sydney into your everyday life.

Probably the most stunning features of Australian art prints is definitely their focus on the country’s well-known natural scenery. Through the majestic Uluru and the steady beaches of Bondi towards the lush rainforests of Queensland and even the rugged Umland, these images capture the breathtaking elegance of Australia’s diverse environments. Art prints of such landscapes permit you to delight in their serenity and even grandeur from anyplace, creating a quiet or inspiring ambiance in your home or work area.

As well as landscapes, Australian wall arts often highlight the country’s amazing wildlife. Kangaroos, koalas, kookaburras, and platypuses are frequently featured in vibrant, detailed pictures or photographs. These types of images not simply add a lively and lively contact to your decoration but in addition serve while a tribute to Australia’s unique fauna, fostering a much deeper appreciation due to its organic biodiversity.

Cultural expression are also prominent in Australian art prints. Indigenous art, having its characteristic dot designs, symbolic motifs, in addition to storytelling elements, plays a vital position in showcasing Australia’s rich Aboriginal historical past. Authentic Indigenous prints can serve since powerful conversation entrepreneurs and cultural connectors, honoring the serious spiritual traditions regarding the land’s 1st Nations people. Choosing such prints provides depth, meaning, and a sense regarding connection to the land’s history.

Contemporary Australian artists add a brand new perspective to be able to the art print picture with their modern styles and contemporary themes. Abstract combinaison, street art influences, and vibrant pallettes reflect Australia’s dynamic urban culture and even artistic evolution. These kinds of modern prints may energize your room and demonstrate the particular country’s creative vibrancy, making them perfect for stylish, contemporary interiors.

Personalization is usually also an essential facet of Australian fine art prints. Many on the web platforms offer modification options, allowing you to choose sizes, framing variations, or even generate personalized compositions. This flexibility ensures of which your selected print suits your existing decoration and becomes an unique expression associated with your connection in order to Australia.

In summary, Australian art print s are a good excellent investment throughout both aesthetic attractiveness and cultural significance. They provide the versatile way to decorate your space together with images that evoke adventure, beauty, plus heritage. Whether a person prefer natural panoramas, wildlife, Indigenous motifs, or modern skill, these prints enable you to celebrate the land Down Under in addition to keep its heart alive inside your daily environment.

Enhance Your Space together with Stunning Australian Frameworked Prints

다낭 마사지 framed prints can be a perfect way to infuse the home or office with the healthy beauty, vibrant tradition, and artistic nature of Australia. These kinds of carefully curated artworks, framed to enhance their particular visual appeal, act as timeless decor bits that can transform any space into a showcase of Down Under’s famous landscapes, wildlife, and even cultural heritage. Whether you’re a passionate vacationer or an regarder of Australian art, framed prints provide a versatile and sophisticated treatment for elevate your current interior design.

Probably the most compelling reasons to be able to choose Australian framed prints is their ability to capture the country’s awe-inspiring landscapes. From typically the rugged cliffs associated with the Twelve Apostles to the peaceful beaches of the particular Whitsundays, these pictures bring a feeling of adventure and even tranquility into your environment. The mounting not simply protects the artwork but likewise adds a polished, finished look, rendering it appropriate for various indoor styles — whether or not modern, rustic, or eclectic.

In addition to natural landscapes, Australian framed pictures often feature images encouraged by Indigenous artwork and symbolism. These artworks carry strong stories and social significance, showcasing classic dot paintings, Dreamtime stories, and remarkable motifs. When presented and displayed thoughtfully, they serve as meaningful decor that raises the bar in Australia’s rich Indigenous heritage while including depth and character to your place.

Contemporary Australian artists also contribute radiant and innovative runs that lend a modern day touch to framed pictures. Abstract compositions, streets art-inspired images, and even bold, colorful styles reflect the dynamic and evolving fine art scene of Sydney. Framing these bits elevates their visual impact, making these people focal points in your own home or workplace. They’re perfect intended for creating an energetic, contemporary atmosphere that will celebrates Australia’s creative spirit.

Personalization is definitely another key advantage of choosing Australian framed pictures. Custom framing options allow you in order to select styles plus materials that go with your decor in addition to highlight the artwork’s best features. No matter if you prefer smooth modern frames or even rustic wooden boundaries, customizing your framed print ensures it is a seamless part of your interior style while preserving the artwork’s vibrancy and detail.

Framed images are also a very good way to preserve reminiscences of your respective travels or special moments connected to Australia. No matter if it’s a panoramic shot in the Good Barrier Reef or perhaps a candid image of native wildlife, surrounding these photos enhances their significance besides making them a lasting keepsake. They can easily be grouped into galleries or viewed as statement items to personalize the space in the meaningful way.

Inside conclusion, Australian framed prints combine artistry, cultural richness, and even aesthetic appeal to create captivating decor pieces that increase any environment. That they offer an advanced method to celebrate Australia’s diverse landscapes, vibrant wildlife, and creative traditions. By picking the proper images and framing them attentively, you could bring typically the spirit of Down under into your home or workspace, making every glance an indication of the land’s extraordinary beauty.

Unlocking Performance: The Ultimate Guide to Fuel Injectors and Their Role in Modern Engines

Introduction: The Heart of Engine Efficiency

In the world of automotive technology, few components are as crucial to engine performance as the fuel injector. Acting as the precise gateway between the fuel tank and the combustion chamber, the fuel injector ensures that the right amount of fuel is delivered at the perfect moment. As engines have evolved from carburetors to sophisticated fuel injection systems, understanding the role of fuel injectors has become essential for car enthusiasts and everyday drivers alike. This article explores the significance of fuel injectors, their types, how they work, and tips for maintaining optimal performance.

The Functionality of Fuel Injectors

Fuel injectors are electronic or mechanical components responsible for atomizing and delivering fuel into the engine’s intake manifold or combustion chamber. They operate based on signals from the engine control unit (ECU), which determines the precise amount of fuel needed depending on factors like engine speed, load, and temperature. When activated, the injector sprays a fine mist of fuel, ensuring optimal combustion, better fuel efficiency, and reduced emissions. Modern vehicles often employ multiple injectors—one for each cylinder—to enhance performance and responsiveness.

Types of Fuel Injectors: Choosing the Right Fit

There are several types of fuel injectors, each designed for specific engine requirements. The most common are port fuel injectors, which spray fuel into the intake ports, and direct fuel injectors, which deliver fuel directly into the combustion chamber. Within these categories, variations include solenoid injectors, piezoelectric injectors, and mechanical injectors. fuel pump -performance applications might use upgraded or aftermarket injectors to increase power output, while standard models focus on reliability and efficiency. Selecting the appropriate injector type depends on your vehicle’s specifications and intended use.

Signs of a Faulty Fuel Injector

A malfunctioning fuel injector can lead to a range of engine problems, often subtle at first. Symptoms include rough idling, decreased fuel efficiency, engine misfires, or increased emissions. You might also notice a strong fuel smell or difficulty starting the engine. Over time, clogged or leaking injectors can cause uneven fuel distribution, resulting in sluggish acceleration and potential engine damage. Recognizing these signs early can help prevent costly repairs and ensure your vehicle runs smoothly.

Maintaining and Replacing Fuel Injectors

Proper maintenance of fuel injectors involves regular cleaning to remove deposits and prevent clogs. Fuel injector cleaning kits are widely available, or professional cleaning services can be performed during routine maintenance. If cleaning doesn’t resolve performance issues, replacing the injectors might be necessary. When replacing, it’s crucial to choose high-quality, compatible parts to ensure longevity and optimal performance. Additionally, using high-quality fuel and maintaining the fuel filter can extend the lifespan of your injectors.

The Future of Fuel Injectors in Automotive Technology

As automotive technology advances, fuel injectors are becoming increasingly sophisticated. Innovations like direct injection, variable nozzle injectors, and integration with hybrid systems are pushing the boundaries of efficiency and performance. Moreover, with the rise of electric vehicles, the role of traditional fuel injectors may evolve, but their underlying principles continue to influence engine design. Researchers are also exploring alternative fuels and injector technologies to meet stricter emissions standards and sustainability goals.

Conclusion: The Key to Optimal Engine Performance

Understanding the vital role of fuel injectors is essential for anyone interested in automotive performance and maintenance. These tiny yet powerful components significantly impact fuel efficiency, emissions, and overall engine health. Whether you’re a car enthusiast looking to upgrade your vehicle or a regular driver aiming to keep your engine running smoothly, paying attention to your fuel injectors can make a noticeable difference. Regular maintenance, prompt repairs, and staying informed about technological advancements will ensure your engine remains efficient and reliable for years to come.

Kiprim Laser Level Review: The Perfect Tool for Precision and Efficiency in Every Project

Accurate leveling is a critical aspect of construction, interior design, and renovation projects. Whether you’re hanging shelves, installing tiles, or aligning cabinets, achieving a perfectly straight line can be challenging without the right tools. The Kiprim Laser Level has emerged as a popular choice among professionals and DIY enthusiasts alike, promising to deliver precise, easy-to-use leveling solutions. In this review, we’ll explore the key features, performance, and benefits of the Kiprim Laser Level to help you determine if it’s the right tool for your needs.

One of the standout features of the Kiprim Laser Level is its high-visibility laser beam. Designed to project bright, clear lines over various distances, this laser level ensures you can see the reference line easily, even in brightly lit environments. Whether you’re working indoors or outdoors, the laser’s brightness and line clarity make alignment tasks straightforward. Additionally, many models come with multiple line modes—horizontal, vertical, or cross-line—allowing users to adapt the tool to different types of projects with ease.

Durability and build quality are vital considerations for any power tool, and Kiprim laser levels do not disappoint. Constructed with rugged materials and protective casing, they are designed to withstand the rigors of job sites, including minor drops and dust exposure. This robustness ensures that the device remains reliable over time, providing consistent performance regardless of the working conditions. The compact and lightweight design also makes it easy to carry and handle, enabling quick setup and operation in tight spaces.

Ease of use is another significant advantage of the Kiprim Laser Level. Many models feature simple, one-button operation combined with intuitive controls, making it accessible even for beginners. The device usually includes a self-leveling mechanism, which automatically adjusts the laser to ensure straight lines without manual calibration. self leveling laser saves time and reduces errors, making your work more efficient and accurate. A clear digital or analog display often helps users confirm the level’s status and settings at a glance.

Battery life and power management are also important factors. Kiprim laser levels are typically equipped with long-lasting rechargeable batteries, ensuring extended use during lengthy projects. Some models also include low-battery indicators, so you know when it’s time to recharge or replace the power source. This reliability means you won’t have to worry about sudden shutdowns in the middle of an important task, boosting productivity and confidence in your results.

The versatility of the Kiprim Laser Level makes it suitable for a wide range of applications. From hanging pictures and installing shelves to more complex tasks like drywall alignment and tile installation, this tool adapts seamlessly. Some models even offer rotating laser heads for 360-degree coverage, allowing for full-room leveling and alignment. Such flexibility makes the Kiprim Laser Level an invaluable addition to any toolbox, whether you’re a professional contractor or a dedicated DIYer.

In conclusion, the Kiprim Laser Level offers a compelling combination of accuracy, durability, ease of use, and versatility. Its bright laser lines and self-leveling features make it a reliable choice for ensuring precision in any project. While it provides excellent value for its price, it’s important to select the model that best fits your specific needs—whether for simple household tasks or more complex professional work. Investing in a Kiprim Laser Level can elevate your craftsmanship and streamline your workflow, making every project more efficient and precise.

Celebrate the Season in Style Why LED Glasses Are the Ultimate Christmas Gift

The holiday season is all about spreading joy, creating memories, and surprising loved ones with gifts that stand out. If you’re looking for a fun, innovative, and eye-catching present, LED glasses are an excellent choice. These luminous accessories are perfect for parties, festivals, or simply adding a touch of sparkle to holiday festivities. Gifting LED glasses this Christmas guarantees a memorable experience and a brightening effect that lasts well beyond the holiday season.

One of the primary reasons LED glasses make an ideal Christmas gift is their ability to transform any gathering into an energetic celebration. Whether it’s a Christmas party, New Year’s countdown, or winter festival, LED glasses add a vibrant glow that captures attention and sets the mood. Their colorful lights sync with music or movement, encouraging everyone to dance, smile, and enjoy the moment. This makes them not just a gift but an experience that everyone will cherish.

The variety of LED glasses available today caters to all ages and styles. From sleek, minimalist designs to bold, flashy patterns, there’s something for everyone. Many models feature customizable lighting modes—flashing, steady glow, or color-changing effects—allowing the wearer to personalize their look. With options that include Bluetooth connectivity, remote controls, and rechargeable batteries, these glasses combine fun with functionality, making them a versatile gift idea for any recipient.

Durability and safety are key considerations when choosing holiday gifts, and LED glasses excel in both areas. Crafted with lightweight, sturdy materials, they’re designed to withstand active use during parties or outdoor events. Most models are rechargeable via USB, making them eco-friendly and easy to maintain. Additionally, Coreida camera smart glasses -resistant lenses and comfortable fit ensure safety and comfort, so recipients can enjoy their glowing accessory worry-free.

Beyond their festive appeal, LED glasses are practical for outdoor winter celebrations or nighttime events. They increase visibility in low-light conditions, helping friends and family stay connected in crowded environments. Whether at a holiday parade, outdoor concert, or a cozy bonfire, LED glasses add a layer of safety while amplifying the fun. Their multifunctional design makes them suitable for both casual wear and party gear.

Gifting LED glasses is also incredibly convenient. They are widely available online and in retail stores, often at affordable prices, making them perfect for last-minute holiday shopping. Compact and lightweight, they can be easily wrapped or tucked into holiday stockings. Plus, many models come with rechargeable batteries, ensuring long-lasting glow and repeated use, making them a smart investment for the festive season.

In conclusion, LED glasses are more than just a trendy accessory—they’re a dynamic, fun-filled gift that brings light and joy to any holiday celebration. Whether you want to surprise a friend, family member, or party host, these luminous glasses are sure to impress and delight. This Christmas, give the gift of glow and help your loved ones shine bright throughout the holiday festivities. Celebrate in style and make this season unforgettable with the perfect pair of LED glasses.

Casting Structure and Design

Technical Specifications

- Model No.: L018516

- Brand: Customizable (OEM/ODM supported)

- Material: High-grade Aluminum Alloy (Compliant with ASTM B85 standards for Aluminum die castings)

- Deck Configuration: Double Deck

- Net Weight: 603.52g (±2g tolerance for consistent production)

- Cavity Number: 2 (Optimized for high-volume manufacturing efficiency)

- Surface Finish: Spray Coating (Corrosion-resistant, scratch-proof; customizable finishes available)

- Production Machine: Cold Chamber Die Casting Machine (Ensures precise metal flow and solidification)

- Precision Tolerance: ±0.05mm for critical dimensions (Meets ISO 8062 Class CT6 standards)

- Maximum Operating Temperature: -40°C to 120°C (Stable performance in harsh environments)

- Mechanical Properties:

- Tensile Strength: ≥220 MPa

- Yield Strength: ≥160 MPa

- Elongation: ≥3% (At 50mm gauge length)

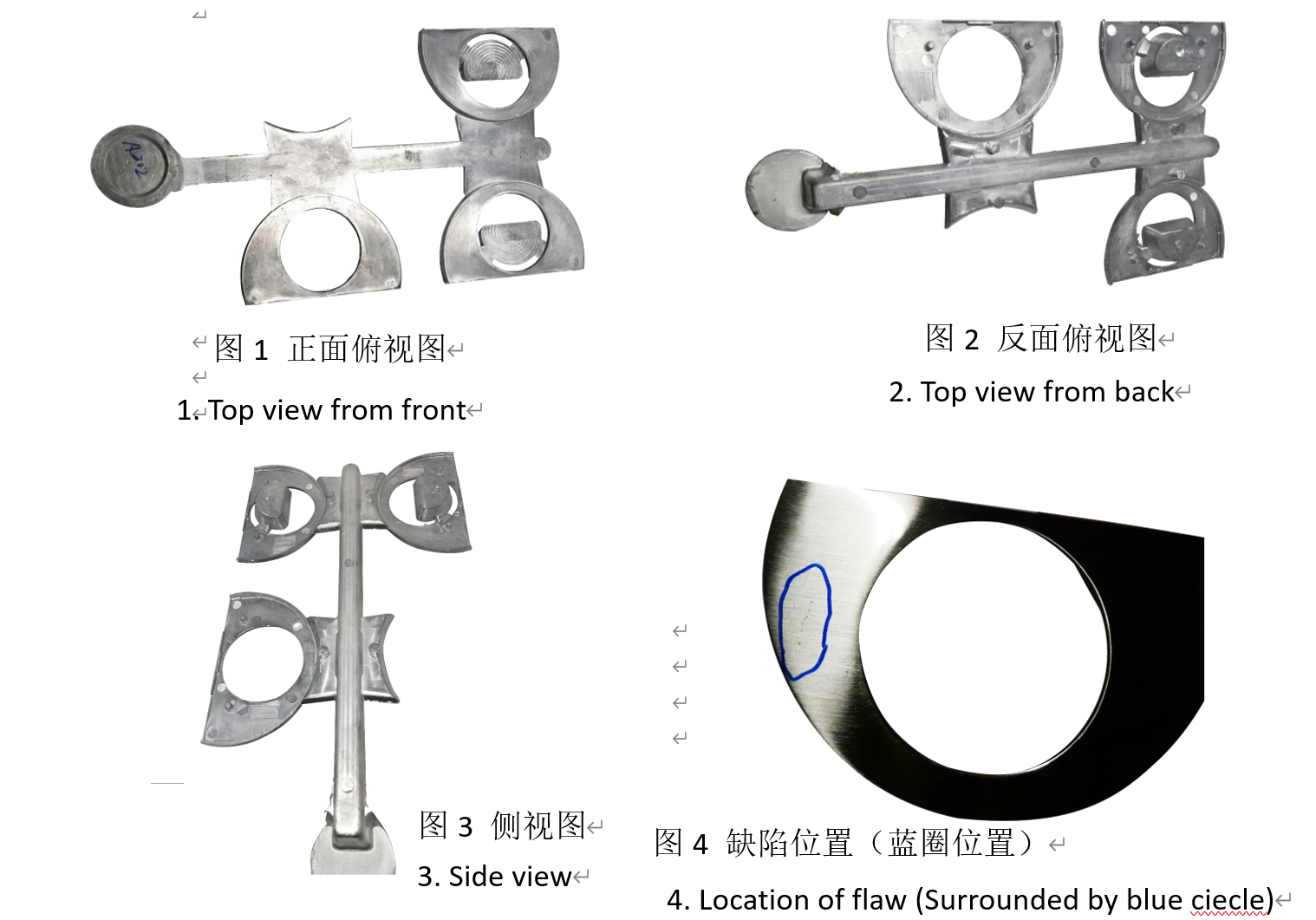

Product Images and Details

1. Casting Structure and Design

Figure 1: Detailed view of the Aluminum Die Casting structure (Model L018516), highlighting the double-deck layout, gating system, and cavity positions—critical for uniform metal flow during production.

2. Finished Casting Photographs

Figure 2: Finished Aluminum die casting (Model L018516) with spray coating surface finish. The image demonstrates the product’s smooth texture, absence of defects (e.g., blisters, scratches), and compliance with surface quality standards.

3. Casting Cross-Sectional Analysis

Figure 3: Cross-sectional view of the Aluminum casting (Model L018516), illustrating optimized internal structure, reduced porosity, and improved flow channel design—key to preventing electroplating blistering and gas entrapment.

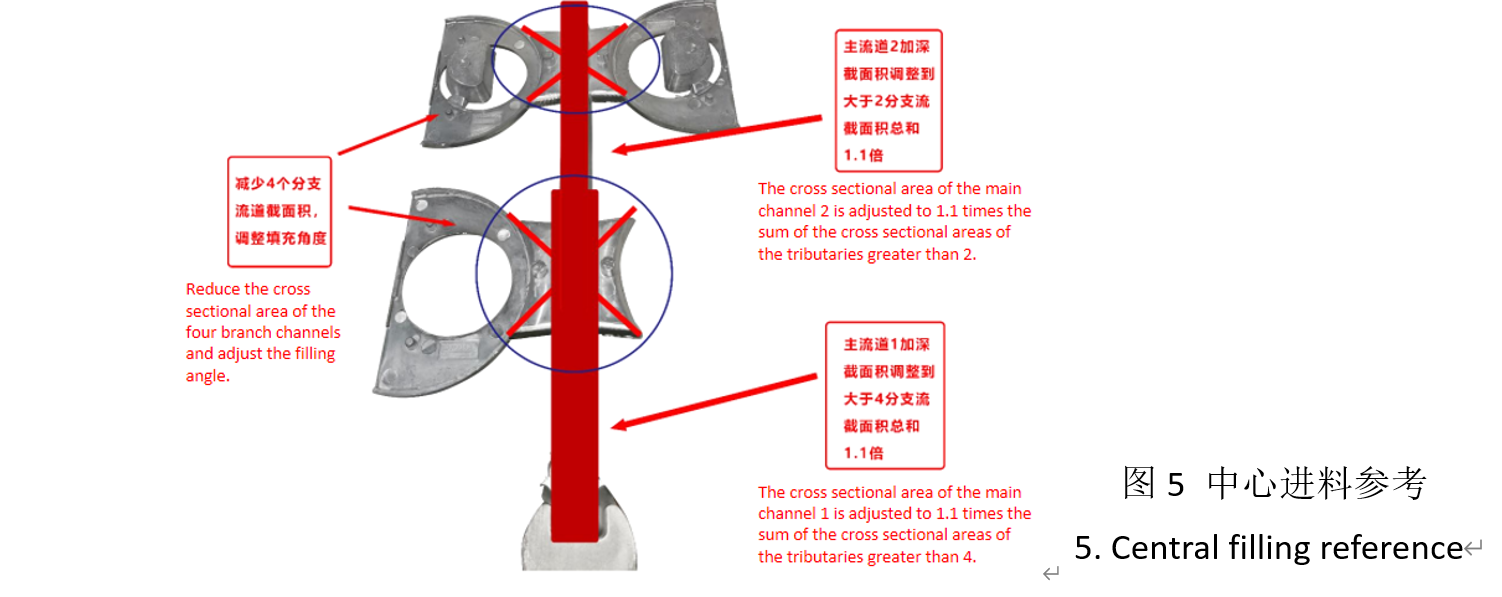

4. Optimized Gating System Design

Figure 4: Improved gating system for the Aluminum die casting (Model L018516). The design includes an enlarged main channel (via deepening) and reduced branch channel cross-sections to minimize gas entrapment and ensure uniform metal filling.

Product Features and Advantages

1. Advanced Cold Chamber Die Casting Technology

Unlike standard die casting methods, our cold chamber machine ensures precise control over aluminum melting temperature (650-700°C) and injection speed. This technology eliminates common defects in Aluminum Castings, such as oxide skin formation and material temperature loss—issues that often lead to poor appearance and electroplating blistering. The result is a product with consistent mechanical properties and surface quality.

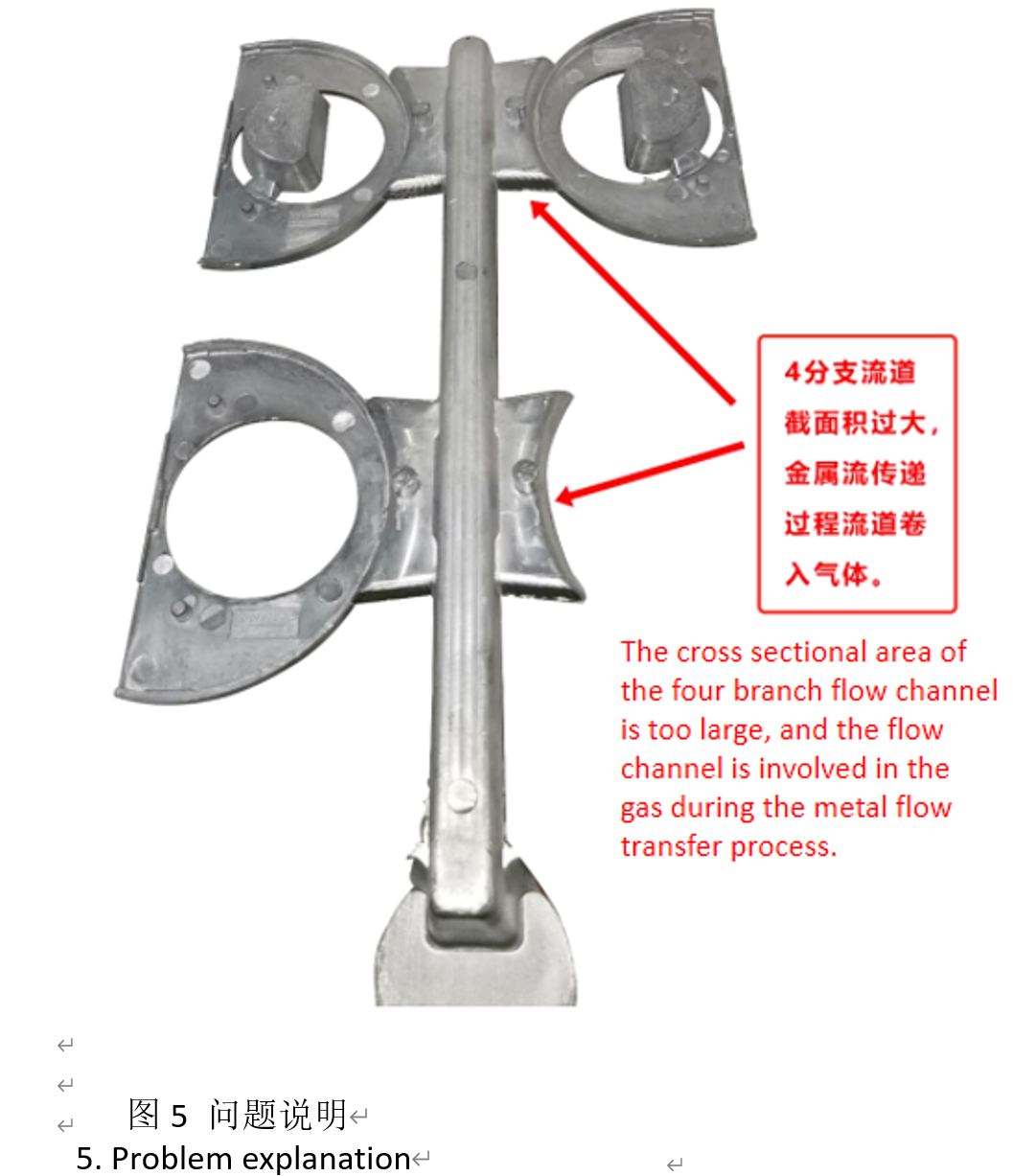

2. Optimized Gating System for Reduced Defects

Addressing a critical industry pain point, we’ve redesigned the gating system of Model L018516 to solve gas entrapment and uneven metal flow:

- Enlarged Main Channel: Due to space constraints, we deepened the main flow channel to increase its cross-sectional area (exceeding the sum of branch channels), ensuring smooth metal transfer and reducing gas absorption.

- Adjusted Branch Channels: Reduced the cross-sectional area of 4 branch channels and optimized filling angles to prevent turbulent flow—key to avoiding internal porosity and surface defects.

- Strategic Gate Placement: Following industry best practices, gates are positioned at the larger end of the casting section to minimize cavity air entrapment. For custom designs, we can reposition gates opposite current locations (as shown in Figure 4) for enhanced performance.

3. Temperature-Controlled Feeding System

To combat material temperature loss—a major cause of casting defects—we’ve integrated a custom oil-heated feeding pipe into the production process. This system maintains consistent aluminum temperature from melting to injection, ensuring optimal fluidity and reducing the risk of oxide skin formation. ForBuyer, this means fewer rejected parts and lower post-processing costs.

4. Double-Deck & 2-Cavity Design for Efficiency

The double-deck configuration and 2-cavity setup of Model L018516 maximize production efficiency:

- Double-deck design reduces machine footprint while increasing output per cycle.

- 2-cavity mold enables simultaneous production of two parts, cutting lead times by up to 30% for high-volume orders.

This efficiency translates to cost savings forBuyer without compromising on quality.

5. Durable Spray Coating Finish

The spray coating surface finish offers multiple benefits:

- Corrosion resistance: Protects the Aluminum die casting from harsh industrial environments (e.g., moisture, chemicals).

- Scratch resistance: Maintains aesthetic appeal and structural integrity during handling and assembly.

- Compatibility with post-processing: Can be easily painted or electroplated (if required) for custom applications.

Advantage Over Competitors

Compared to standard Aluminum die castings in the market, Model L018516 stands out in three key areas:

- Defect Rate: Our optimized processes reduce defects (e.g., blistering, porosity) to less than 1%, compared to the industry average of 5-8%.

- Production Speed: 2-cavity design and cold chamber technology enable 20% faster output than single-cavity alternatives.

- Customizability: We offer flexible adjustments to surface finish, cavity number, and dimensions—unlike rigid “one-size-fits-all” products from competitors.

How to Integrate and Handle the Aluminum Die Casting

Step 1: Pre-Installation Inspection

- Unpack the Aluminum die casting (Model L018516) and check for surface damage (e.g., scratches, dents) using visual inspection—refer to Figure 2 for quality benchmarks.

- Verify dimensional accuracy with calibrated tools (e.g., calipers, micrometers) to ensure compliance with your assembly requirements (tolerance: ±0.05mm).

- For electroplating or additional coating: Clean the surface with a mild alkaline solution to remove residual release agents—this prevents adhesion issues.

Step 2: Assembly Integration

- Position the double-deck casting in your assembly fixture, aligning with mounting holes (if applicable). Use non-abrasive clamps to avoid surface damage.

- For parts requiring fastening: Use aluminum-compatible screws (e.g., stainless steel) with torque settings of 2-3 N·m—over-tightening may cause deformation.

- If integrating with other components (e.g., electronic modules, mechanical parts), ensure clearance for thermal expansion (aluminum expands ~23.1 μm/m·°C).

Step 3: Post-Installation Quality Check

- Conduct a leak test (if used in fluid-handling applications) to ensure no porosity or cracks—our casting’s cross-sectional integrity (Figure 3) minimizes failure risk.

- Test mechanical performance (e.g., load-bearing capacity) within the product’s rated limits (tensile strength ≥220 MPa) to confirm durability.

Step 4: Maintenance Guidelines

- Clean the casting periodically with a dry cloth—avoid harsh solvents that may damage the spray coating.

- Store unused parts in a dry, temperature-controlled environment (15-25°C, relative humidity ≤60%) to prevent oxidation.

- For long-term use: Inspect the coating annually for wear—reapply spray coating if signs of corrosion appear.

Application Scenarios

Our Aluminum die casting (Model L018516) is versatile enough to serve multiple industries, thanks to its durability, precision, and customizable design. Below are key application areas whereBuyer have successfully integrated this product:

1. Automotive Industry

- Component Use: Double-deck castings for engine cooling systems (e.g., radiator brackets, coolant channels) and electronic control unit (ECU) enclosures.

- Why It Works: High temperature resistance (-40°C to 120°C) and corrosion resistance (spray coating) withstand under-hood conditions. The 2-cavity design enables mass production to meet automotive volume demands.

2. Electronic & Electrical Industry

- Component Use: Housings for industrial sensors, power inverters, and 5G base station modules.

- Why It Works: Aluminum’s excellent thermal conductivity (160 W/m·K) dissipates heat from electronic components, while the spray coating provides electrical insulation. The double-deck design saves space in compact devices.

3. Industrial Machinery

- Component Use: Structural parts for conveyor systems (e.g., roller brackets) and hydraulic valve bodies.

- Why It Works: High tensile strength (≥220 MPa) and low weight (603.52g) reduce machinery load while ensuring durability. The optimized gating system eliminates internal defects, preventing fluid leaks in hydraulic applications.

4. Medical Equipment

- Component Use: Frames for portable medical devices (e.g., ultrasound machines) and sterilization tray holders.

- Why It Works: Non-toxic aluminum material complies with medical industry standards (e.g., ISO 10993). The smooth spray coating is easy to clean and sterilize, reducing contamination risk.

Benefits for InternationalBuyer

- Cost Savings Through Efficiency: The 2-cavity mold and cold chamber technology reduce production time by 20-30%, lowering unit costs for high-volume orders (MOQ: 4000 pieces). Additionally, our optimized processes cut defect rates to <1%, minimizing scrap and rework expenses.

- Reliable Quality for Global Markets: Compliant with international standards (ASTM B85, ISO 8062), our Aluminum die castings meet the regulatory requirements of regions like the EU (CE), North America (ANSI), and Asia (JIS). This eliminates barriers to market entry forBuyer.

- Customization to Fit Unique Needs: We offer adjustments to surface finish (e.g., anodizing, powder coating), cavity number (1-4 cavities), and dimensions—ensuring the product aligns with your specific assembly or design requirements. No more compromising on “standard” parts.

- Reduced Lead Times: With a dedicated production line for Aluminum castings, we deliver orders in 4-6 weeks (for standard specs) and 8-10 weeks (for custom designs)—faster than the industry average of 8-12 weeks.

- Long-Term Durability: The combination of high-grade aluminum, spray coating, and defect-free production ensures the casting has a service life of 5+ years in industrial applications. This reduces maintenance costs and replacement frequency forBuyer.

- Transparent Supply Chain: We provide real-time production updates and quality reports (including cross-sectional analysis, as in Figure 3) throughout the order process—givingBuyer full visibility and peace of mind.

Certifications and Compliance

Our Aluminum die casting (Model L018516) and production processes adhere to strict international standards, ensuring quality and compliance for globalBuyer. Below are key certifications and compliance credentials:

- ISO 9001:2015: Quality management system certification, covering all stages from design to delivery—ensuring consistent product quality.

- ASTM B85-20: Standard specification for aluminum-alloy die castings, verifying material purity and mechanical properties.

- ISO 8062 Class CT6: Dimensional tolerance standard for die castings, confirming our ±0.05mm precision meets global requirements.

- RoHS Compliance: Free of hazardous substances (e.g., lead, mercury) to meet EU and global environmental regulations.

- CE Certification: Valid for sales in the European Economic Area (EEA), ensuring compliance with health, safety, and environmental protection standards.

- IATF 16949:2016 (Optional): For automotiveBuyer, we offer IATF-certified production processes—specifically tailored to automotive industry quality requirements.

We provide certification documents with every order, enablingBuyer to streamline their own regulatory approvals.

Customization Options

We understand that everyBuyer has unique needs. Beyond the standard Aluminum die casting (Model L018516), we offer flexible customization to align with your specific application, design, and branding requirements:

1. Material Customization

- Aluminum Alloy Grades: A380 (standard), A383 (higher strength), A413 (heat-resistant) — selected based on your application’s mechanical and thermal needs.

- Material Additives: Optional trace elements (e.g., magnesium, silicon) to enhance specific properties (e.g., corrosion resistance, machinability).

2. Design & Dimensional Customization

- Deck Configuration: Single or triple-deck designs (beyond the standard double-deck) to fit space constraints.

- Cavity Number: 1, 3, or 4 cavities (adjusted for production volume needs—1-cavity for prototypes, 4-cavity for maximum output).

- Dimensions: Custom length, width, and height (up to 500mm × 300mm × 200mm) with precision tolerances as tight as ±0.02mm for critical features.

- Mounting Features: Integrated holes, threads, or slots (drilled or tapped during production) to eliminate post-processing.

3. Surface Finish Customization

- Coating Types: Anodizing (clear, black, or colored), powder coating (textured or smooth), or electroplating (nickel, chrome) — ideal for aesthetic or functional needs (e.g., conductivity, corrosion resistance).

- Branding: Laser engraving of logos, part numbers, or QR codes (for traceability) on the casting surface.

4. Production Process Customization

- Quality Testing: Additional tests (e.g., X-ray inspection for internal defects, salt spray testing for corrosion resistance) beyond our standard quality control.

- Packaging: Custom packaging (e.g., anti-static bags, labeled cartons) to protect parts during shipping and align with your inventory systems.

Our engineering team provides free design-for-manufacturability (DFM) analysis for custom orders—ensuring your design is optimized for die casting, cost-effective, and high-quality.

Production Process & Quality Control

1. Production Flow for Aluminum Die Casting (Model L018516)

- Design & Mold Fabrication:

- Engineers use CAD software to finalize the casting design (including gating system, as shown in Figure 4) and conduct simulation tests to predict metal flow and defect risks.

- Mold fabrication: High-grade H13 steel is used to create the 2-cavity mold, with heat treatment to ensure durability (mold life: 500,000+ cycles).

- Material Preparation:

- Aluminum alloy ingots are melted in a furnace at 650-700°C, with degassing agents added to remove impurities (e.g., hydrogen) that cause porosity.

- The molten aluminum is transferred to the cold chamber machine via the custom oil-heated feeding pipe (to prevent temperature loss).

- Die Casting:

- The cold chamber machine injects molten aluminum into the mold at high pressure (80-120 MPa) and speed (2-5 m/s), ensuring full cavity filling.

- The mold is cooled with water channels to control solidification time—critical for dimensional accuracy.

- Trimming & Deburring:

- Automated trimmers remove excess material (e.g., sprue, runners) from the casting.

- Robotic deburring tools smooth edges to meet surface finish requirements (Ra ≤ 1.6 μm).

- Surface Treatment:

- The casting undergoes spray coating (standard) or custom finishes (e.g., anodizing) in a controlled environment to ensure uniform coverage.

- Coated parts are cured at 180-200°C for 30 minutes to enhance adhesion and durability.

- Final Inspection & Packaging:

- Parts are inspected for quality (dimensions, surface defects, mechanical properties) before being packaged in moisture-proof cartons.

2. Strict Quality Control Measures

- In-Process Inspection:

- Material temperature is monitored every 10 minutes to ensure it stays within 650-700°C.

- Every 50th casting is checked for dimensional accuracy using a CMM (Coordinate Measuring Machine) to verify compliance with ISO 8062 Class CT6.

- Post-Production Testing:

- Visual inspection: 100% of parts are checked for surface defects (e.g., blisters, scratches) against Figure 2’s quality standard.

- Mechanical testing: Random samples undergo tensile strength and elongation tests to confirm compliance with ASTM B85.

- Cross-sectional analysis: As shown in Figure 3, samples are cut and polished to check for internal porosity or cracks—reject rate for non-compliant parts is <1%.

- Traceability: Each batch is assigned a unique lot number, linking to production records (material source, machine parameters, inspection results) for 5 years—enabling easy recall if needed.

Customer Testimonials

“We’ve been using Model L018516 Aluminum die castings for our automotive radiator brackets for 2 years. The defect rate is less than 0.5%, which is way below our previous supplier’s 7%. The 2-cavity design also cut our lead time by 25%—critical for meeting our production deadlines.”

— Marco Rossi, Procurement Manager, AutoParts S.p.A. (Italy)

“As a manufacturer of medical devices, we need castings that meet strict quality and safety standards. This Aluminum casting’s RoHS compliance and smooth spray coating make it perfect for our ultrasound machine frames. The customization team also adjusted the mounting holes to fit our design—no extra machining needed.”

— Sarah Chen, Engineering Director, MedTech Innovations (USA)

“We ordered 10,000 units of Model L018516 for our industrial sensor housings. The thermal conductivity of the aluminum keeps our sensors cool, and the double-deck design saves space in our devices. The team provided real-time production updates, and the order arrived 1 week early—excellent service.”

— Kim Ji-hoon, Supply Chain Manager, TechSensor Co. (South Korea)

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for Model L018516?

A1: The standard MOQ is 4000 pieces. For prototype or small-batch orders (100-1000 pieces), please contact our sales team—we offer flexible terms for new customers or custom designs.

Q2: Can you provide samples before mass production?

A2: Yes. We can produce 5-10 sample pieces of the Aluminum die casting (Model L018516) within 2 weeks. Samples include full quality reports (dimensional tests, surface finish checks) to confirm compliance with your requirements. Sample costs are refundable if you place a mass production order of ≥4000 pieces.

Q3: What is the lead time for standard and custom orders?

A3: For standard Model L018516 (spray coating, 2-cavity), lead time is 4-6 weeks. For custom orders (e.g., different alloy, surface finish, or cavity number), lead time is 8-10 weeks (includes mold adjustment and testing).

Q4: Do you offer testing reports for the aluminum die castings?

A4: Yes. Every order includes a detailed quality report with:

- Dimensional inspection results (CMM data).

- Mechanical property test results (tensile strength, elongation).

- Surface finish analysis (Ra value).

- Certification copies (ISO 9001, ASTM B85, RoHS).

Additional tests (e.g., X-ray, salt spray) are available upon request for an extra fee.

Q5: What payment terms and incoterms do you accept?

A5:

- Payment Type: T/T (Telegraphic Transfer) — 30% deposit upon order confirmation, 70% balance before shipment.

- Incoterms: FOB, CFR, CIF, FCA ( Ningbo or Shanghai ports).

- For long-term customers, we offer flexible payment terms (e.g., 50% deposit, 50% balance after delivery).

Q6: How do you handle damaged or defective parts?

A6: We take full responsibility for any parts that do not meet the agreed quality standards. If you receive damaged or defective Aluminum castings:

- Notify us within 7 days of receiving the order, with photos and a detailed description of the issue.

- We will arrange for a replacement shipment (free of charge) or issue a refund—whichever you prefer.

- For critical orders, we can expedite replacements to minimize your production downtime.

Our defect rate is <1%, so this issue is rare—but we have a clear process to resolve it quickly.

Q7: Can you support OEM/ODM projects beyond Model L018516?

A7: Absolutely. We specialize in custom Aluminum die castings for OEM/ODM projects. Our engineering team will work with you to design castings that meet your exact specifications (material, dimensions, finish). We also offer mold design and fabrication services for unique designs—contact us with your CAD files or concept, and we’ll provide a free DFM analysis and quote.

Order & Shipping Information

1. Order Process

- Submit your inquiry: Provide details (quantity, specifications, customization needs) via email or our website form.

- Quote & sample: We send a detailed quote within 2 business days. If needed, we produce samples (2-week lead time) for your approval.

- Order confirmation: Once you approve the sample and quote, we issue a proforma invoice. You pay the 30% deposit to start production.

- Production & inspection: We update you on production progress weekly. Before shipment, we send a quality report for your review.

- Shipment: After you pay the 70% balance, we arrange shipping via your preferred method (ocean, land, air) from Ningbo or Shanghai port.

2. Shipping Details

- Transportation Options: Ocean (most cost-effective for large orders), Land (for regional orders in Asia/Europe), Air (expedited shipping for urgent orders).

- Export Ports: Ningbo, Shanghai (major Chinese ports with global connectivity).

- Shipping Time:

- Ocean: 20-30 days to Europe/USA, 7-14 days to Southeast Asia.

- Air: 3-5 days to most global destinations.

- Land: 5-10 days to neighboring countries (e.g., Vietnam, Thailand).

- Packaging: Standard packaging is moisture-proof cartons (20 pieces per carton, gross weight ≤20kg). Custom packaging (e.g., pallets, anti-static bags) is available upon request.

3. Contact Us for Orders

To place an order or inquire about our Aluminum die casting (Model L018516) or custom Aluminum castings, please contact our sales team:

- Email: sam@bldiecasting.com

- Phone: +86-18157495020

- Website: https://www.bldiecasting.com/ (submit inquiry via the “Contact Us” form)

Our team speaks English, Spanish, and German—we’re available 24/7 to answer your questions and support your procurement needs.

Small Business Grants Your Entrance to Funding Accomplishment and Growth

Starting or expanding a small business often calls for significant capital, plus while loans and investments are frequent routes, grants present an excellent opportunity to secure funding without the burden of repayment. Small business grants are cash provided by government agencies, private foundations, and even corporations to help entrepreneurs grow their particular ventures, innovate, and even create jobs. Comprehending how to gain access to these grants can make a substantive difference in transforming your business desires into reality.

A single of the biggest advantages of small enterprise grants is they carry out not require repayment, which is why they are concidered an appealing option for startups and established businesses alike. These funds can be employed for various purposes—such as purchasing equipment, funding r and d, marketing and advertising, or hiring fresh employees. However, because they are extremely competitive, it’s vital to carefully researching available grants and prepare strong, tailored applications that obviously demonstrate your business’s value and potential.

There are numerous sources of small organization grants available throughout federal, state, and even local levels. National programs often give attention to innovation, technology, in addition to economic development, although state and local grants may concentrate on community revitalization or even minority-owned businesses. In addition, many private fundamentals and corporations provide grants aligned along with their corporate sociable responsibility goals or even industry focus areas. Staying informed via official websites, regional business associations, plus industry networks may help you discover opportunities early.

Making use of for your own business grant involves reveal procedure. Applicants usually will need to submit a comprehensive business plan, financial statements, and a new compelling narrative detailing how the grants funds will end up being used. It’s essential to align your proposal with typically the grant’s objectives, putting an emphasis on how your company will positively effect the community, generate jobs, or advance innovation. Attention to detail, clarity, and even adherence to rules can significantly enhance your likelihood of accomplishment.

Winning your own business give can do greater than provide financial support—it can also increase your credibility plus visibility. Many scholarhip programs include general public acknowledgment, that may enhance your reputation within your industry and neighborhood. Moreover, the process of applying often helps entrepreneurs refine their business techniques, improve financial administration skills, and better understand their target marketplaces. These benefits may be as beneficial since the monetary prize itself.

Managing the grant responsibly is usually essential for sustaining good standing and even future eligibility. People are typically expected to submit development reports, financial paperwork, and evidence of how the funds are utilized. Failing to conform to these requirements may jeopardize current grants and disqualify you from future funding. Developing strong record-keeping methods and maintaining translucent communication with grant administrators are key to long-term success.

To conclude, small business grants can be a powerful useful resource for entrepreneurs trying to find funding that doesn’t require repayment. Together with diligent research, very careful planning, and dependable management, these scholarships can provide essential capital to assist your company grow, pioneer, and succeed. minority business grants is fierce, the benefits of securing some sort of grant can be transformative, opening doors to new opportunities and even long-term success in a competitive marketplace.